Dental Technology

Milling centre

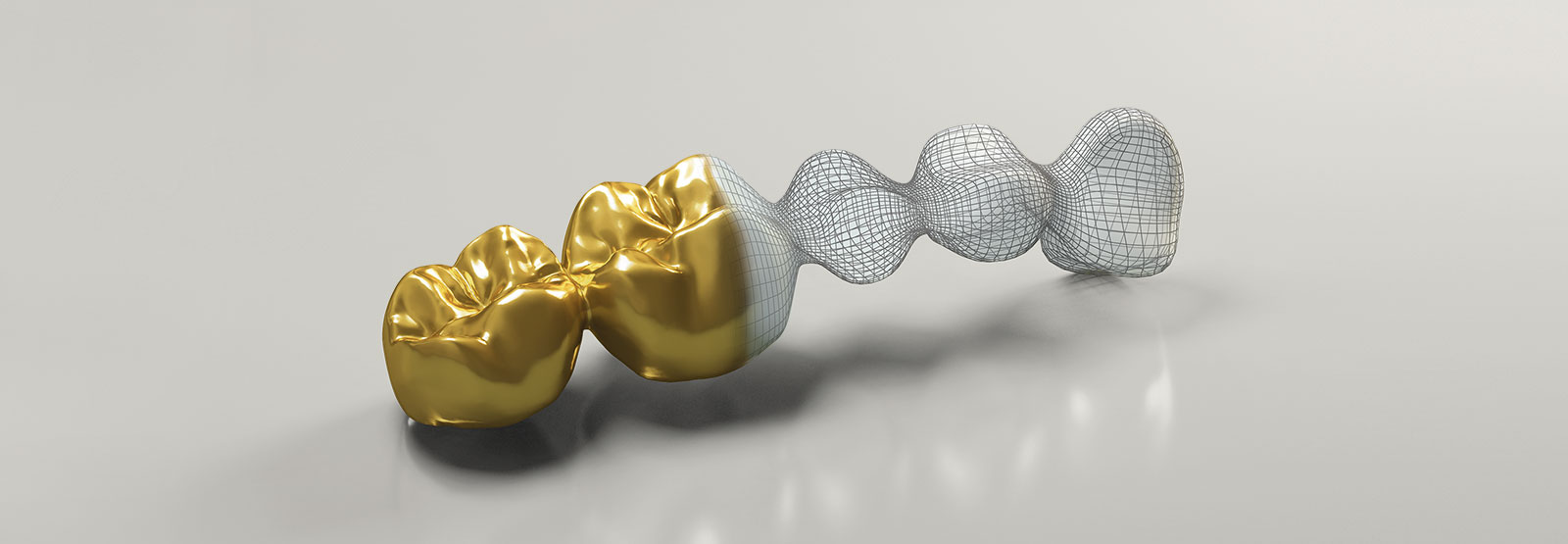

The digital process chain is also available for restoring precious metals. The procedure fits seamlessly into already existing digital processes within the practice and laboratory. After an intraoral or model scan, transferring the design data in the open *.stl format to our digital production centre is quick and easy. Here, the designed items are made from precious metal alloys using the milling process and shipped to the client within two working days. The time-consuming production of the frameworks in the company’s own factory is no longer necessary, nor is the cost-intensive storage of precious metals.

Digital manufacturing – the cost-effective solution for every laboratory

Cost-effective production

Cost-effective production

Integrating the precious metal into the digital manufacturing process eliminates the need to maintain two different manufacturing processes (casting and digital manufacturing) in the laboratory. There is no need for expensive pre-financing and warehousing of precious metals.

Perfect material quality

Perfect material quality

The material quality of precious metals, which is already very high, is further improved by processing precious metal in a digital process. The already very high material quality of precious metals is further improved by the industrial production of milling blanks with special processes, making cavities, pores or impurities a thing of the past. A perfect microstructure facilitates further processing in the laboratory whether through ceramic veneering or polishing.

Material savings of up to 30%

Material savings of up to 30%

Digital CAD design with evenly thin wall thicknesses allows for a reduction in the weight of finished pieces by up to 30% over cast structures. A milled unit weighs on average only 2 grams.

Milling technology

cehaGOLD frameworks are cut from solid blanks of precious metals using state-of-the-art 6-axis milling machines. Careful adaptation of the milling strategies to the different precious metal alloys and indications guarantees an accurate fit as well as outstandig quality. The final step is a quality inspection followed by dispatch to the dental laboratory.

Alloys

Applications

Innovative digital offers cater for all applications of prosthetic treatment*. Six tried and tested high-grade precious metals alloys are used for production.

* Component height is max. 15 mm. This may be exceeded in special cases.

Telescopes

All-in-One manufacturing

As a supplement and further development of the product milling in precious metal, there is now the possibility of producing telescopic work in precious metal in a new process. With the telescopic combination technique, the design as well as the production of the primary and secondary parts each take place simultaneously in one work step. In the All-in-ONE process, the time-consuming and error-prone scanning of the polished primary parts is completely eliminated. You only have to supply the data sets for the primary and secondary parts in one step.

Within seven working days, the precision-fit telescope work with finished polished primary parts is in the laboratory. All you have to do is set your desired individual friction. In the case of a combined analogue-digital process with conventional impression taking, plaster model fabrication and model scanning, one additional working day is to be expected.

The design can be done with exocad DentalCAD (from version 5675) or 3Shape Dental Designer (from version 2.8.8.5). The installation of the required material library All-in-ONE is done by the C.HAFNER support team. And if a primary telescope from an All-in-ONE job should ever get lost or broken, a new one can be ordered with just one call.

The advantages of All-in-ONE for the dental laboratory

- Time saving

- Material saving

- Consistently good fit and quality

- calculability of manufacturing costs and profit margin

Take advantage of our attractive trial offer and test our innovative “Precious metal milling” service: Your milling units will be manufactured for free until further notice – you only pay the alloy list price plus 10% processing loss! You are welcome to contact your sales representative to discuss individually adjusted terms and conditions.

Digital manufacturing in non-precious metals, ceramics and plastics

The fully digital process chain

C.HAFNER offers all the services of a milling and service centre via Dental Direkt – not only in the field of precious metals, but also in non-precious metals, ceramics and plastics. Increase efficiency in the digital lab with safe and user-friendly products. Our range of services includes all the services of a modern milling centre.

Take advantage of our attractive trial offer and test our innovative “Precious metal milling” service: Your milling units will be manufactured for free until further notice – you only pay the alloy list price plus 10% processing loss! You are welcome to contact your sales representative to discuss individually adjusted terms and conditions.

Sicherheitsdatenblätter

Digital manufacturing in non-precious metals, ceramics and plastics

The fully digital process chain

C.HAFNER offers all the services of a milling and service centre via Dental Direkt – not only in the field of precious metals, but also in non-precious metals, ceramics and plastics. Increase efficiency in the digital lab with safe and user-friendly products. Our range of services includes all the services of a modern milling centre.

Data

We process *.stl data from open CAD systems such as Dental Designer (3Shape), Exocad or DentalWings. Our technical support team will gladly assist you in setting up the corresponding parameters (settings). Technical support can be reached on +49 (0)7044 90333 1236.

Prices

We mill crowns and bridges (also fully anatomical), inlays and onlays, telescopes and bars for you.

The price per milling each unit is €30. (not applicable for trial offer)

Additional retentions will be charged at €15, attachments at €30.

We calculate the used precious metal weight at the current list price minus precious metal markdown plus a processing loss of 10%.

Dispatch terms

We guarantee delivery within 48 hours (not inclusive of postage time) if data is received by 4:30 p.m., after which the 48-hour period for the next working day (Mon-Fri) begins.

Alternatively, we offer express production - delivery within 24 hours (not inclusive of postage time) for data received by 12pm and carries an additional charge of €9.50 per unit. If the data is received after 12p.m., the 24-hour period begins on the next working day (Mon-Fri).

We have no control over the delivery times stipulated by the postal service. You can choose between standard mail delivery (EUR 5.90) or express delivery - before 12pm the following day (EUR 14.40).

All prices are exclusive of VAT. Prices subject to change.

Your contact

Precious metal dental technology

Tel.: +49 7044 90 333-333

edelmetall-dentaltechnologie@c-hafner.de

![[Translate to Englisch:] schwarzer Hintergrund mit goldene](https://www.c-hafner.de/fileadmin/user_upload/bild-text/c-hafner-bildtext-teleskope-allinone-fertigung.jpg)